Acceptance (Testing of Goods)

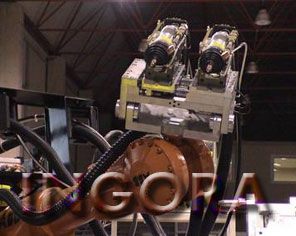

Testing which uses both vision & robotic technology, relates to: Robotic acquisition of component or product to be tested. Robotic loading of component or product into testing fixture. Robotic controller communication with testing controller. Robotic sorting of product or component based on test results. Surface & feature location (flexible gauging) verification utilizing robots & sensors.

Testing which uses both vision & robotic technology, relates to: Robotic acquisition of component or product to be tested. Robotic loading of component or product into testing fixture. Robotic controller communication with testing controller. Robotic sorting of product or component based on test results. Surface & feature location (flexible gauging) verification utilizing robots & sensors.

Marking

Any marker machine can be adaptable with a robot arm to act as its end-effector. We hereby explain an example, plasma marking, which is an excellent method of signing mild steel, stainless steel or all electrical conductive material. A plasma torch & low current power source up to 20 Amperes is used to plasma mark. Dots, letters, lines, assembly signs, … are easily produced with a speed from 3 m/min or 120 ipm up to 18 m/min 700ipm. Amperage can be directly controlled & monitored by the controller. The line width can be set to a constant line width from 0.6 mm or .020″ to 3 mm or .12″.This guarantees exceptional marking accuracy. One of the biggest advantages of plasma marking is the capability to mark on wet, oily or rusted surface. Also, the consumable lifetime is very long compared to conventional plasma because the marking is at low amperage. As with normal plasma applications, the plasma torch is installed on an anti-collision protection device, which avoids damaging the torch main body. By adjusting the current & speed to suit your application, the plasma mark can be seen or hidden after a galvanization, sandblasting or painting, depending on the customer wishes.

Any marker machine can be adaptable with a robot arm to act as its end-effector. We hereby explain an example, plasma marking, which is an excellent method of signing mild steel, stainless steel or all electrical conductive material. A plasma torch & low current power source up to 20 Amperes is used to plasma mark. Dots, letters, lines, assembly signs, … are easily produced with a speed from 3 m/min or 120 ipm up to 18 m/min 700ipm. Amperage can be directly controlled & monitored by the controller. The line width can be set to a constant line width from 0.6 mm or .020″ to 3 mm or .12″.This guarantees exceptional marking accuracy. One of the biggest advantages of plasma marking is the capability to mark on wet, oily or rusted surface. Also, the consumable lifetime is very long compared to conventional plasma because the marking is at low amperage. As with normal plasma applications, the plasma torch is installed on an anti-collision protection device, which avoids damaging the torch main body. By adjusting the current & speed to suit your application, the plasma mark can be seen or hidden after a galvanization, sandblasting or painting, depending on the customer wishes.

Inspection

Many vision-guided robot cells utilize inspection vision capability. Machine vision can be utilized in robotic assembly cells for both robot guidance & inspection of either incoming parts or the completed assembly. The vision system recognizes the incoming parts on the flexible feeder, the part orientation, & whether the part is accessible for robotic acquisition. Parts that are not accessible are bypassed & are recycled in the flexible feeder. In bakeries, a product typically emerges from the cooking process on a moving stainless conveyor & is manually assembled or transferred to the consumer package or wrapper in-feed. Robots in automated systems assemble & transfer cookies, doughnuts, biscuits, & bread items from the oven line to the packaging line & organize them for consumer presentation. The robots use machine vision to locate & inspect the individual product items. Multiple robot cells vacuum-pick baked items from the main conveyor to achieve required throughput. Machine precision is possible for the placements, although it’s not usually required!A newly spreaded application for robots in petroleum industry is pipe & vessel inspection. The pipe explorer robot uses a pneumatically operated airtight tubular membrane to tow radiation detectors & video cameras into pipes. It can be used to move a characterization tool forward & backward through a pipe as the tool’s output & position are continuously recorded, providing detailed characterization of the location, visual appearance, & quantity of radioactive contamination in pipes.

Many vision-guided robot cells utilize inspection vision capability. Machine vision can be utilized in robotic assembly cells for both robot guidance & inspection of either incoming parts or the completed assembly. The vision system recognizes the incoming parts on the flexible feeder, the part orientation, & whether the part is accessible for robotic acquisition. Parts that are not accessible are bypassed & are recycled in the flexible feeder. In bakeries, a product typically emerges from the cooking process on a moving stainless conveyor & is manually assembled or transferred to the consumer package or wrapper in-feed. Robots in automated systems assemble & transfer cookies, doughnuts, biscuits, & bread items from the oven line to the packaging line & organize them for consumer presentation. The robots use machine vision to locate & inspect the individual product items. Multiple robot cells vacuum-pick baked items from the main conveyor to achieve required throughput. Machine precision is possible for the placements, although it’s not usually required!A newly spreaded application for robots in petroleum industry is pipe & vessel inspection. The pipe explorer robot uses a pneumatically operated airtight tubular membrane to tow radiation detectors & video cameras into pipes. It can be used to move a characterization tool forward & backward through a pipe as the tool’s output & position are continuously recorded, providing detailed characterization of the location, visual appearance, & quantity of radioactive contamination in pipes.

Flexible gauging (Measurement)

The requirements which leads a sample car manufacturer to use of robots for flexible gauging are:

The requirements which leads a sample car manufacturer to use of robots for flexible gauging are:

• Increase product quality by implementing trend analysis to modify frame production methods prior to product quality tolerances exceeding acceptable limits, & prior to body-in-white transfer to the painting operation;

• Improve yields & reduce product rework costs by applying 100% inspection of critical fit-points, normally done by CMM machines on just one body per day;

• Free up metrology lab to complete more product quality inspection tasks;

In addition to meeting the immediate needs listed above, envisioned future benefits to robotic in-line gauging, including reduction of launch time for new models, correction of component quality problems at the supplier’s site, & elimination of expensive checking fixtures.

The six-axis robot system with 3D laser sensor cameras is chosen over a traditional CMM approach because of its flexibility & speed. Six-axis robots mounted with laser sensor cameras are also, more flexible & cost-effective than fixed camera solutions. Fixed camera solutions require one sensor for each characteristic inspected but, four robots each with a single sensor will be sufficient to measure more than 130 characteristics!

Dipping (Submerged Coating)

A method for dip coating a substrate with organic polymers may increase the efficiency of light-emitting diodes (LEDs) & computer displays while reducing costs & environmental hazards.

A method for dip coating a substrate with organic polymers may increase the efficiency of light-emitting diodes (LEDs) & computer displays while reducing costs & environmental hazards.

The technique, being explored by a group of MIT researchers, uses the natural affinity of opposite electrical charges to make coatings that are as thin as a single layer of molecules.

The researchers begin with a substrate, which most often has a natural, slightly negative electric charge. They dip the substrate into a bath of a positively charged polymer that has been dissolved in water. The polymer responds to the charge of the substrate by sticking to it tightly. For the next layer, the researchers switch back to negatively charged molecules, which stick to the positive surface. Researchers have layered as many as 25 substances on a single substrate. Using computers & robotic dipping mechanisms, the researchers can automate the process.

The Swiss firm, “Luber” has developed its core coating systems consisting of an automatic processing system that features an agitating container, circulating pump, water pouring equipment & an electric control panel & a dip tank for robotic dipping within an area of 1000 x 800 mm.

Clean-room Robots (Ultra-precision Operation)

The necessary characteristics for a robot which is suitable to be applied in a compact clean room make the robot to move at high speed & with very high repeatability. This together with the compact design, long reach & the ability to mount the robot in an inverted position, makes it ideal for assembly & testing lines for small electronic goods such as mobile telephones, radios, etc. The robot should also, be suitable for packing the finished products.

The necessary characteristics for a robot which is suitable to be applied in a compact clean room make the robot to move at high speed & with very high repeatability. This together with the compact design, long reach & the ability to mount the robot in an inverted position, makes it ideal for assembly & testing lines for small electronic goods such as mobile telephones, radios, etc. The robot should also, be suitable for packing the finished products.

The necessary characteristics for a robot which is suitable to be applied in a compact clean room make the robot to move at high speed & with very high repeatability. This together with the compact design, long reach & the ability to mount the robot in an inverted position, makes it ideal for assembly & testing lines for small electronic goods such as mobile telephones, radios, etc. The robot should also, be suitable for packing the finished products.