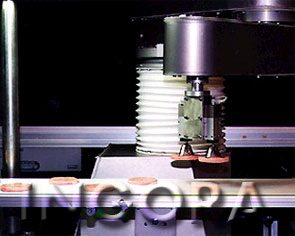

Loading & Unloading (Machine Tending)

For many companies, the time to automate material handling has arrived. That’s because minimizing manual intervention in handling ingredients or components, work-in-process, & finished products can improve quality, productivity & operator well-being, while reducing costs. Forces driving the decision to automate include:

For many companies, the time to automate material handling has arrived. That’s because minimizing manual intervention in handling ingredients or components, work-in-process, & finished products can improve quality, productivity & operator well-being, while reducing costs. Forces driving the decision to automate include:

• Manpower reductions due to downsizing;

• The need to improve operator working conditions by eliminating or minimizing heavy lifting, repetitive motions & noise;

• A desire for faster throughput;

• Customer requirements for more customized products, just-in-time delivery & order entry & receiving via electronic data interchange;

• Quality demands;

• The proliferation of point-of-sale information;

• Avoiding surplus inventory at all levels of the company’s supply chain.

• In the same way that today’s downsized work forces are expected to do more with less, material-handling equipment is also increasingly flexible, versatile & compact.

So, robots can be applied simultaneously together with a hydraulic press, lathe, CNC, or a machine center. Most essential, however, is an effort to integrate material handling into the manufacturing process & bring information handling & material handling closer together.

While big retailers & their suppliers have been pioneers in using real-time POS information to convert to demand-driven production & maintain inventories at the lowest possible level until the last moment, makers of durable goods are just beginning to think about such changes. Yet, it’s in the durable-goods sector that the greatest benefits will be realized.

Pick & Place (Part Sorting)

Pick-&-place robots have been used in a variety of material handling applications, including palletizing or depalletizing, case picking, kitting, machine loading or unloading, parts feeding, & parts delivery.

Pick-&-place robots have been used in a variety of material handling applications, including palletizing or depalletizing, case picking, kitting, machine loading or unloading, parts feeding, & parts delivery.

Pick-&-place robots are typically stationary, pedestal-mounted robots. Therefore their work envelope is limited. To increase the work envelope & serve more machines, a Pick-&-place robot can be installed on a gantry crane, resulting in a gantry robot. Some agriculture tasks such as sorting of oysters & dried mushrooms or animal meat grading can be automated by using robots. Successful applications requires the capability of adapting to variations in the fish/carcass size/shape/orientation, which has been achieved by developing force feedback control & continuous path planning & image processing feedback.

For a sample application, several tasks may be automated by using robots in the preparation of airline meals; In preparation of the kits, silverware must be sorted out of the washer. Machine vision, used in conjunction with a robotic picker, can reassemble the knife-fork-spoon combinations. Standard condiments & dishes are placed to the tray line using robots working from known feed locations. Salads, desserts, & entrees may also be placed; a “smart” gripper enables one robot to handle a wide variety of tray & dish sizes.

Packaging (Pack Filling)

A common manual task is packing bags off a vertical form-fill-seal (VFFS) machine to cases. Robots are also used to pack sausages from bulk to a horizontal form-fill-seal machine (HFFS). Vacuum grippers pick a four-sausage array from random positions, alternating the curvature, & move them to the package cavity for placement. Robots can place the sausages even when the HFFS is indexing. Packing of pill assortments to blister packages has been automated with vision-guided robots.Robots pack fancy candies in their display cartons. A multiple robot line uses vision-guided robots to locate the individual chocolates appearing randomly on the incoming conveyor, & then place them at specific locations on their tray, which moves on a continuous moving carton line.

A common manual task is packing bags off a vertical form-fill-seal (VFFS) machine to cases. Robots are also used to pack sausages from bulk to a horizontal form-fill-seal machine (HFFS). Vacuum grippers pick a four-sausage array from random positions, alternating the curvature, & move them to the package cavity for placement. Robots can place the sausages even when the HFFS is indexing. Packing of pill assortments to blister packages has been automated with vision-guided robots.Robots pack fancy candies in their display cartons. A multiple robot line uses vision-guided robots to locate the individual chocolates appearing randomly on the incoming conveyor, & then place them at specific locations on their tray, which moves on a continuous moving carton line.

Palletizing (Package Arranging)

Robots are available for palletizing cases after they are filled. Cases are typically presented on a conveyor single file, & need to be picked & stacked on standard pallets. Stacking patterns are variable, based on case dimensions, & with multiple products (cases) running at one time the palletizing robot may need to serve several pallets. The working area is arranged to accommodate all of the pallets & allow forklift access for removing complete loads. Softwares have been developed that enable creation of pack patterns based on optimal density & stacking strength. Usually, a 3D graphic presentation aids in visualizing the complete layers inside the pallet. The pattern is established off-line on a PC & then downloaded to the robot.

Robots are available for palletizing cases after they are filled. Cases are typically presented on a conveyor single file, & need to be picked & stacked on standard pallets. Stacking patterns are variable, based on case dimensions, & with multiple products (cases) running at one time the palletizing robot may need to serve several pallets. The working area is arranged to accommodate all of the pallets & allow forklift access for removing complete loads. Softwares have been developed that enable creation of pack patterns based on optimal density & stacking strength. Usually, a 3D graphic presentation aids in visualizing the complete layers inside the pallet. The pattern is established off-line on a PC & then downloaded to the robot.

Dynamic Warehousing (Storage Management)

Automated storage & retrieval systems play a significant role both in manufacturing & warehousing. Under complete computer control, these systems can store, keep track of, & retrieve a large number of part types & containers. In manufacturing they have been used successfully for work-in-process storage on the factory floor. In warehousing they have been used in component/raw materials storage as well as order picking.

Automated storage & retrieval systems play a significant role both in manufacturing & warehousing. Under complete computer control, these systems can store, keep track of, & retrieve a large number of part types & containers. In manufacturing they have been used successfully for work-in-process storage on the factory floor. In warehousing they have been used in component/raw materials storage as well as order picking.

A carousel, which can operate under complete computer control, is used typically for small to medium parts storage & retrieval. It consists of a set of floor-supported or suspended revolving bins that rotate to bring the containers to the Position/Deposition point. If rotation is horizontal (such as a carousel one might find at a dry cleaner), it’s termed a horizontal carousel. If rotation is vertical (such as a carousel one might find at a hospital with many patient files), it’s termed a vertical carousel.

Flexible Fixturing (Indexing Hard Tooling)

The concept of flexible fixturing has been around a long time. Systems employing variations of hard tooling have been used for years. Systems based on variations of hard tooling frequently sub optimize the product mix flexibility, convertibility, & speed to market, floor space, & simplicity. However, through application of the proven benefits of robotics to fixturing, these shortcomings can be & are being addressed. In fact, automotive & aircraft manufacturers have already implemented or are in the midst of developing reconfigurable fixturing systems.

The concept of flexible fixturing has been around a long time. Systems employing variations of hard tooling have been used for years. Systems based on variations of hard tooling frequently sub optimize the product mix flexibility, convertibility, & speed to market, floor space, & simplicity. However, through application of the proven benefits of robotics to fixturing, these shortcomings can be & are being addressed. In fact, automotive & aircraft manufacturers have already implemented or are in the midst of developing reconfigurable fixturing systems.

The next generation of flexible fixturing systems has achieved its flexibility via servo-driven programmable positioners.

The ability of flexible fixturing systems to teach & shim location positions quickly allows plants to minimize downtime during startup & operation, resulting in operational savings. However, the initial capital investment for a flexible fixturing system can sometimes exceed the cost of a hard tooling variation.

AGVs (Automatic Transportation)

An AGV (Automatic Guided Vehicle) is an automated handling device that can move unit loads from one point to another point with no human intervention & under computer control. Guidance is typically provided by a wire (embedded in the floor), & movement typically occurs on a horizontal plane.

An AGV (Automatic Guided Vehicle) is an automated handling device that can move unit loads from one point to another point with no human intervention & under computer control. Guidance is typically provided by a wire (embedded in the floor), & movement typically occurs on a horizontal plane.

The trend toward greater flexibility is nowhere more apparent than in automatic guided vehicles (AGVs) where non-wire guidance is replacing wired paths. Laser navigation systems provide accuracy to +/-5 millimeters & complete freedom of movement, making it easy to change or extend routes.

Wire guidance is more common, but laser is probably most preferred now. Another big advantage of laser-guided systems is installation simplicity. You don’t have to tear up the floor.

Laser guidance systems transmit invisible light which is reflected by reflector tapes mounted on walls & other objects along the route. An on-board computer knows the location of the tapes & can calculate the AGV’s position. Instructions for pick-ups & deliveries are transmitted via infrared or RF by a stationary dispatch computer. A new teach-in device simplifies route modifications by simply storing the route in memory as